As a way to provide the Harvard University innovation community with more prototyping and manufacturing resources, the Harvard Innovation Lab Ecosystem has doubled the size of its prototyping lab. The expansion meets the growing hardware design and iteration demands of student-led startups, and also fulfills the need for a “maker-space” for teams working in the i-lab and the Launch Lab.

This in-house resource improves efficiency for startups working on product design and development, helps to increase the slack time for the go-to-market readiness of products, and gives hardware-based startups handy and affordable access to high-caliber tools and equipment. The prototyping lab will also serve as another way for the like-minded innovators that make up the Innovation Lab Ecosystem community to connect and work on projects together.

From developing bicycle helmets to robotic arms to wearable health sensors for elite athletes, the prototyping lab plays a pivotal role supporting entrepreneurs and startup teams in the Venture Incubation Program. It eliminates the added expenses — for the i-lab’s student-led startups — that can come with outsourcing design, prototyping, and manufacturing to outside labs and third parties. The prototyping lab is a resource for any student that has access to the i-lab from across Harvard’s 13 schools, as well as the teams working out of the Launch Lab co-working space for Harvard alumni ventures.

“Being able to quickly produce prototypes is critical in the development process for the teams operating in the i-lab,” said Jodi Goldstein, Managing Director of the Harvard Innovation Lab Ecosystem. “Our goal is to expand our reach and provide resources to the teams that help them get further, faster. The refined and improved lab space will provide the tools for enhancing product design and enable students to focus on their business ideas.”

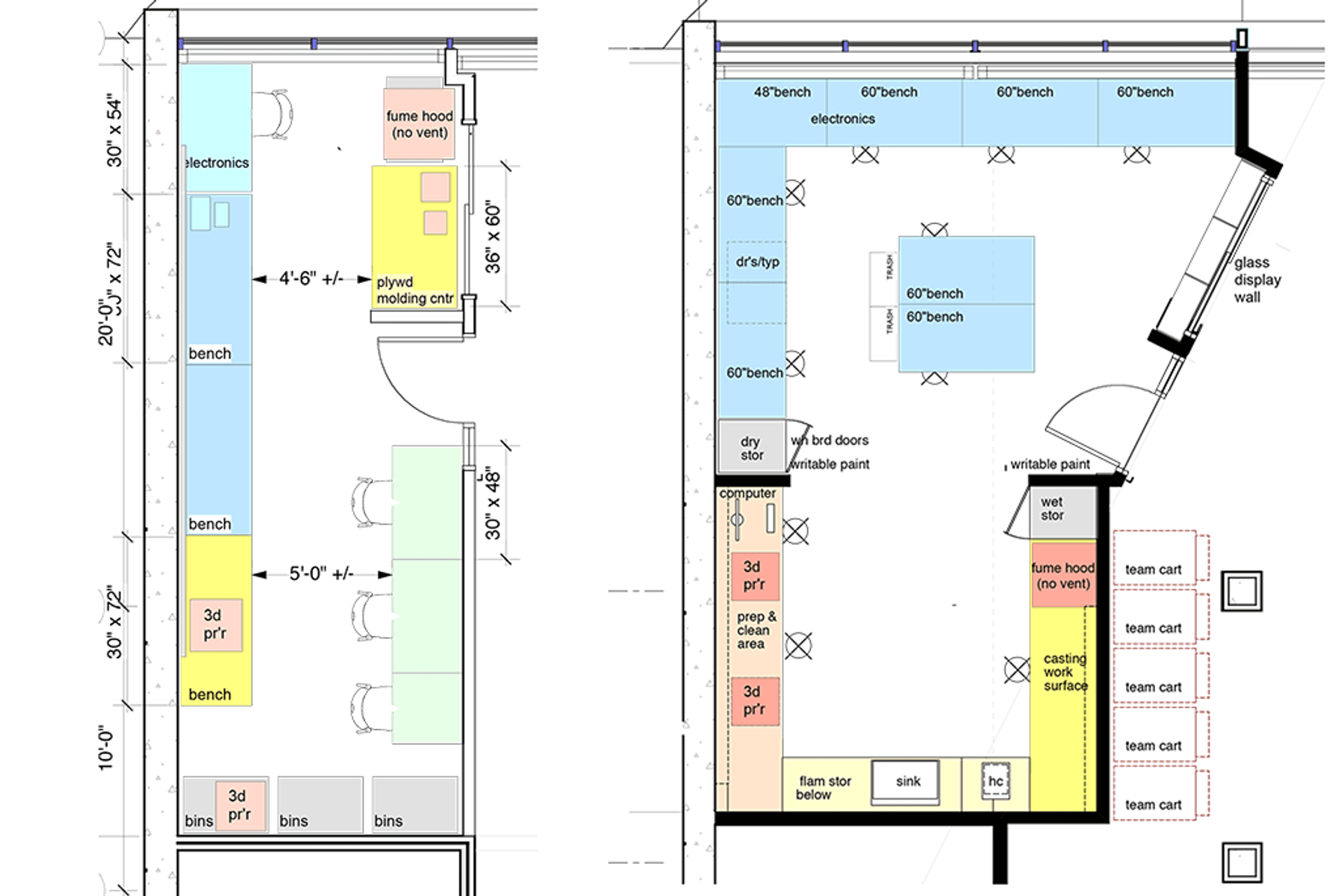

Developed from the input of those students who have used the prototyping lab in its previous incarnation, the key features of the expanded lab include a wet zone and dry zone, a new 3-D printer resources, collaborative team space, and assembly, manufacturing, rubber molding, and soldering areas. A lab manager provides training to users and general oversight of the lab in order to provide both expertise in working with the equipment and to address safety needs.

“We make robots, and this place initially had no really great area for us to test them out, but the new space was indispensable to help us get to where we are right now,” said Lael Odhne, co-founder and technical lead of former i-lab resident RightHand Robotics.

“For startups, quick product iterations are imperative, so having the space to actually work is very important,” added RightHand Robotics co-founder Yaro Tenzer. “It is great to have access to tools for casting, access to 3-D printing, and access to manufacturing, basically right next to your business development operations. The workshop area is so close that you can take a prototype you’ve just built and bring it over to entire team to discuss and iterate.”